Ductfab Equipments Pvt. Ltd.

DUCTFAB EQUIPMENTS PVT. LTD.

Ductfab Equipments Pvt. Ltd.

DUCTFAB EQUIPMENTS PVT. LTD.

Introducing the DUCTFAB Beading Machine, a game-changer for medium and small duct manufacturers. Our Beading Machines are designed to simplify and enhance the duct fabrication process, providing a significant advantage for duct manufacturing industry.

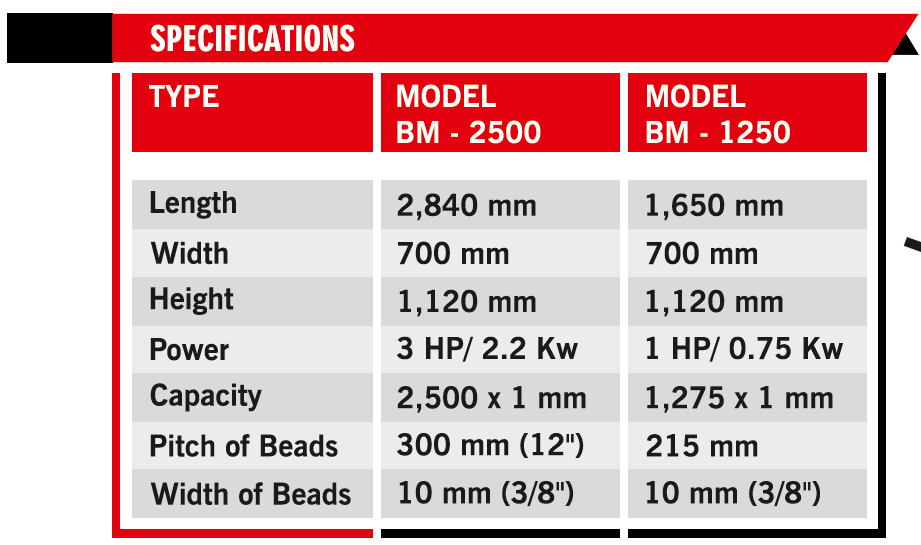

Upgrade your duct manufacturing capabilities with the DUCTFAB Beading Machine BM – 1500 & BM - 2500. Experience the advantages of advanced technology, efficiency, and precision, leading to stronger, more professional-looking ducts. Say goodbye to the age-old hand methods and embrace the future of duct fabrication with our cutting-edge Beading Machine.