Ductfab Equipments Pvt. Ltd.

DUCTFAB EQUIPMENTS PVT. LTD.

Ductfab Equipments Pvt. Ltd.

DUCTFAB EQUIPMENTS PVT. LTD.

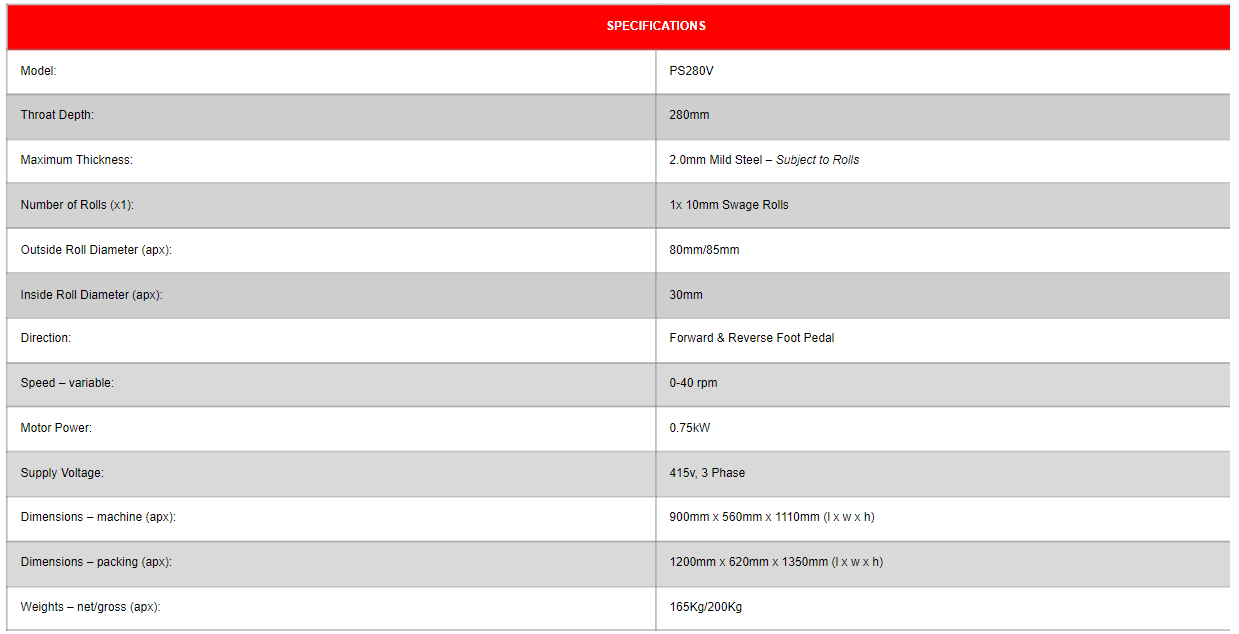

Introducing DUCTFAB Hand and Power Swager Machines – precision-engineered tools designed for exceptional productivity and extended operational life in the sheet metal fabrication industry. These swaging machines are adept at achieving a variety of profiles through the utilization of different roll types, ensuring versatility for a wide range of applications. With the inclusion of hardened forming rolls, these machines are built for durability. The power machines are available in two models: PS 215 and PS 280.

These DUCTFAB Swager Machines are meticulously crafted to meet the demands of a dynamic sheet metal fabrication environment, offering a combination of reliability, versatility, and efficiency for achieving diverse profiles. Whether using the power models or the manual HS 215, elevate your swaging capabilities with DUCTFAB's robust and powerful swager machines.